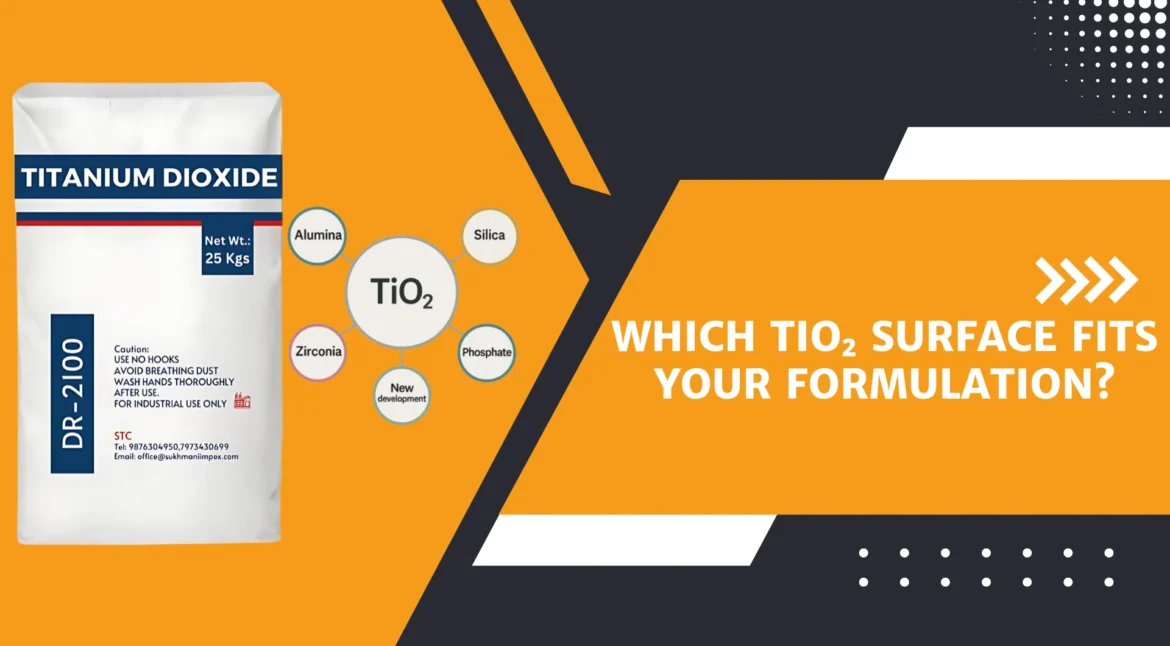

Which TiO₂ Surface Fits Your Formulation?

Titanium Dioxide (TiO₂) is the most popular white-colored pigment in the world. It is valued for its high brightness, high refractive index, and opacity. At Sukhmani Impex, we understand that surface treatment is vital for the functionality of your formulation, whether it is a coating, plastic, ink, cosmetic, or paper.

But the real question is: Which TiO₂ surface best fits your formulation?

In this blog we will discuss the differences between coated and uncoated TiO₂, rutile and anatase, and help you choose the best titanium dioxide to match your product.

Understanding TiO₂ Surface Treatments

The surface characteristics of TiO₂ particles are critical in understanding the behavior of TiO₂ in your formulation. TiO₂ is frequently surface-treated with inorganic materials (for example, Alumina, Silica, or Zirconia) and, sometimes, organic coatings to increase functionality.

1. Coated TiO₂

These grades are intended for enhanced performance in commercial and industrial applications.

Applications:

- Paints & coatings (interior and exterior)

- Masterbatches and PVC

Examples of Coated TiO₂ from Sukhmani Impex:

- DR-945 – High-performance for plastics and coatings

1.1 Alumina-Coated TiO₂

- Key Benefits: Improved dispersion, reduced reactivity

- Advantages: Better gloss, opacity, and tinting strength

- Ideal For: Paints, inks, powder coatings, water-based systems

1.2 Silica-Coated TiO₂

- Key Benefits: Enhanced UV stability and weathering resistance

- Advantages: Excellent for outdoor exposure, better color retention

- Ideal For: Automotive finishes, exterior paints, high-durability coatings

1.3 Zirconia-Coated TiO₂

- Key Benefits: High chemical resistance, durability

- Advantages: Supports aggressive processing conditions

- Ideal For: High-performance plastics, films, specialized coatings

1.4 Silica + Alumina Coated TiO₂

- Key Benefits: Balanced UV resistance & dispersion

- Advantages: Multi-functional—enhanced gloss, stability, and compatibility

- Ideal For: Premium coatings, cosmetics, and personal care products

1.5 Phosphate-Coated TiO₂

- Key Benefits: Excellent dispersion in polar systems

- Advantages: Reduced agglomeration, improved processability

- Ideal For: Waterborne coatings, adhesives, and inks

2. Uncoated TiO₂

These are more reactive and are generally reserved for controlled environments or specialty applications.

- Key Benefits: High brightness and opacity

- Limitations: UV sensitivity, less stability

Ideal For: Cost-effective formulations in indoor coatings, plastics

3. Organic Surface-Treated TiO₂

- Key Benefits: Improved wetting and compatibility with organic systems

- Advantages: Better flow properties, easier processing

- Ideal For: Plastics, rubber, and solvent-based formulations

Example:

- DR-2400 – A bright anatase TiO₂ ideal for ink and paper industries

Crystal Structure: Rutile and Anatase

Rutile TiO₂

- Higher refractive index (≈2.7) = better opacity

- Naturally more stable under UV exposure

- Preferred for outdoor and high-durability applications

Anatase TiO₂

- Lower refractive index (≈2.5)

- Offers better whiteness and dispersibility

- Often used in indoor, cosmetic, or specialty applications

Crystal Structure: Rutile and Anatase

Rutile TiO₂

- Higher refractive index (≈2.7) = better opacity

- Naturally more stable under UV exposure

- Preferred for outdoor and high-durability applications

Anatase TiO₂

- Lower refractive index (≈2.5)

- Offers better whiteness and dispersibility

- Often used in indoor, cosmetic, or specialty applications

Which TiO₂ surface fits which industry and formulation:

| Industry | Recommended TiO₂ Type | Surface Treatment | Product Suggestion |

| Paints & Coatings | Rutile | Coated (alumina/silica) | DR-945, DR-2100 |

| Plastics & PVC | Rutile | Coated | DR-2400, DR-945 |

| Cosmetics | Rutile or Anatase | Coated (food/cosmetic grade) | SA-171, SA-216 |

| Paper & Ink | Anatase | Uncoated | SA-216, DR-2100 |

| Ceramics & Glass | Anatase | Uncoated | SA-216 |

| Masterbatch | Rutile | Coated | DR-2400 |

| Food Contact | Rutile (Food Grade) | Coated | SA-216 |

| Electrorods | Anatase | Uncoated | SA-1000E |

| Photocatalytic Surfaces | Anatase | Uncoated | SA-216 |

Why the Right Surface Matters

Using the wrong TiO₂ surface can lead to:

- Poor dispersion and sedimentation

- Decreased gloss or brightness

- Yellowing or degradation over time

- Reduced product lifespan in UV or heat

Sukhmani Impex assists our clients with data-driven, applications-driven decisions. Every formulation has a behavior, and determining the right TiO₂ grade can mean ‘good’ to ‘great.’

Our Titanium Dioxide Portfolio

Want to learn more about the TiO₂ we offer? Explore our full range:

👉 View Our TiO₂ Grades

👉 Contact Us

📞 Is it still unclear which TiO₂ surface is best for your formulation?

Our technical team can help you, working to understand the coatings you are seeking. Whether you are seeking a premium architectural coating or a bright White masterbatch, we will help you choose the TiO₂ that has the best performance for the price. ( sales@sukhmaniimpex.com)