What are Internal and External Lubricants for PVC Pipe?

The purpose of lubricants for PVC pipe is to facilitate the connection of pipe segments, particularly while fittings or connectors are being inserted. Lubricants lessen friction, which facilitates the process and lowers the possibility of internal and external pipe (fitting) damage.

PVC pipe lubricants are essential products that make it easier to connect pipe segments and fittings during the installation process. Internal and External Lubricants for PVC Pipe. They protect the pipes and fittings from damage and ensure a smooth and efficient installation by reducing friction. Lubricants make it less likely for pipes to bind or make fittings more difficult to insert. Lubricants also help create strong, leak-proof connections, which are crucial for maintaining the integrity of the piping system.

Introducing Fluid-X by Sukhmani Impex

Fluid-X is a uniquely formulated lubricant by Sukhmani Impex, which is intended to provide internal as well as external lubrication in PVC processing.

It is made with Paraffin Wax, PE Wax, and Stearic Acid. This ready-to-use lubricant reduces friction, enhances pipe fitting, and makes mold release easy.

Seamless Assembly

Durably Safe Application

Suitable for Internal & External Use

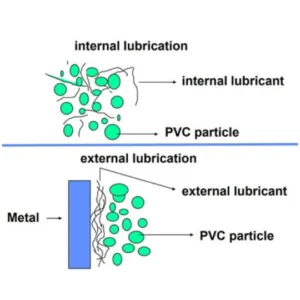

internal and external lubrication

internal and external lubrication

Common Types of Lubricants:

Internal lubricants reduce friction inside pipes, while external lubricants ease joining with fittings during installation.

Common lubrication types for PVC pipes are covered in this article, including silicone, water, and grease-based lubricants.

- Water-based: Safe for potable water systems, non-toxic.

- Grease-based: Not suitable for heavy-duty applications, drinking water systems.

- Silicone-based: Works in both wet and dry conditions.

1. Internal Lubricants

Internal Lubricants The pipes are fitted inside the PVC pipe so that one pipe can be easily inserted into another pipe or into a fitting. This reduces friction, which prevents damage when inserting the pipe into the fitting.

Purpose: The purpose of Internal lubricants is to reduce friction. With the help of these lubricants fitting of pipes during insertion gets easier.

Common types of internal lubricants:

- Fatty acids and esters: These substances, which include glycerol monostearate and stearic acid, lower melt viscosity.

- Metallic stearates and glycerides: These substances, which include magnesium stearate, calcium, and zinc, enhance flow characteristics.

- Waxes: Paraffin and microcrystalline waxes are two examples of waxes that can improve surface smoothness and lessen the likelihood that PVC will adhere to processing equipment.

-

Ester and oxidized polyethylene waxes commonly improve the clarity of the final product and disperse fillers in the PVC composite.

The perfect internal lubricant, Fluid-X enhances the flow of molten PVC and the quality of the final product.

Additionally, it improves the precision of the lubricant used in PVC products and uses less energy. In addition, it lowers friction and guards against wear and tear.

2. External Lubricants

In order to minimize friction and avoid sticking during handling, storing, and installing PVC pipes, external lubricants are applied to their surfaces.

Simple but dangerous, pipe fitting can result in damage and challenging assembly.

Common types of external lubricants:

- Paraffin wax: This external lubricant, frequently used for PVC pipes, has good releasing qualities and lowers friction.

- Polyethylene wax: Users frequently use this wax with paraffin wax to enhance the lubricating qualities and surface.

- Silicone-based: Using silicone can keep the PVC pipe from adhering to molds or other surfaces.

- Specialty: The company made these especially for PVC applications to achieve the best results.

The most well-known external lubricant is Fluid-X, which makes sure that PVC products come out of molds or dies easily. It provides a smooth surface by lowering the likelihood of sticking and ripping.

Key differences of PVC pipe

Key differences of PVC pipeDifferences of Lubricants for PVC :

Internal lubricants are used within PVC pipes to lessen friction during fitting or pipe insertion, simplifying assembly and avoiding damage. They are primarily silicone-, oil-, or water-based. External lubricants reduce friction, aid connection, and prevent fitting-pipe damage. with a petroleum or water base are common.

-

Internal lubricants are used inside the pipe to smooth up pipe fittings or segment insertion and avoid binding or sticking.

-

Workers externally lubricate pipes and fittings to facilitate connection and guard against damage during installation.

A company called Sukhmani Impex might offer a range of PVC pipe-related goods, such as Fluid-X, made to make installation simpler. It is advised to get in touch with Sukhmani Impex directly or visit their website to learn more about their unique products and applications if you are seeking lubricants for PVC pipes.

I suggest looking at Sukhmani Impex’s product catalog or contacting their sales team for more detailed information on the particular lubricants they offer.