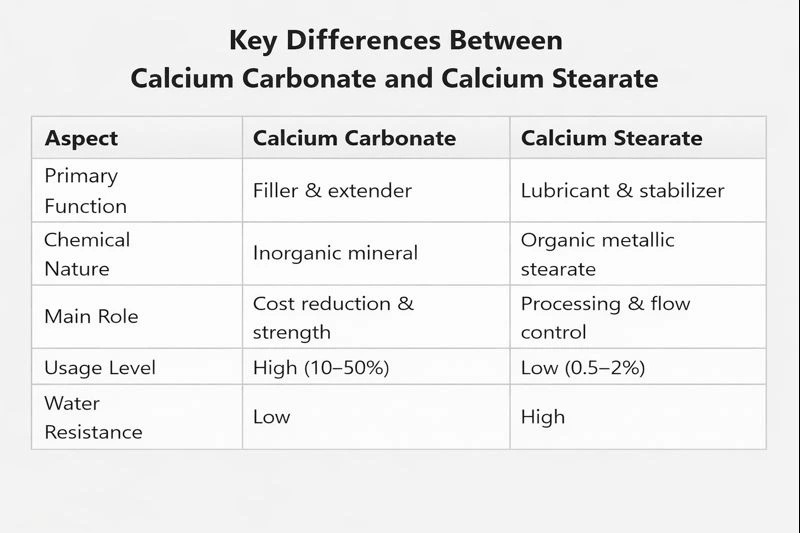

Calcium Carbonate vs Calcium Stearate are calcium-based materials, but each has unique uses depending on the industrial application. It is important to select the properly matched material for each specific application to improve a product’s durability, surface finish, and overall processing efficiency in the many industries of PVC processing and plastic production. Understanding these differences between Calcium Carbonate and Calcium Stearate to maximise performance, quality, and cost effectiveness in their products.

What is Calcium Carbonate?

Definition

Calcium Carbonate is a type of mineral that has an inorganic chemical composition and exists naturally in the form of limestone, marble or chalk. In industry, Calcium Carbonate powder is manufactured as fine powder with controlled particle size and purity through several industrial processes.

Industrial Applications

Calcium Carbonate is intended primarily for use as a filler & functional extending agent in a multiple of industries.

- PVC Pipe & fittings.

- Plastic Compound & Masterbatch.

- Paint & coatings & Construction Material.

- Rubber & Cable insulation.

In PVC manufacturing, Process, the use of Calcium Carbonate can help reduce the overall cost of the raw materials needed to produce PVC pipe additives, and also improve their rigidity.

Benefits of Calcium Carbonate

- Cost-effective; that is low-cost raw material.

- Improved stiffness and dimensional stability.

- Improved opacity and surface finish.

- Easy to disperse into polymer matrices.

Because of these advantages, Calcium Carbonate powder is among the most widely consumed mineral fillers throughout the world.

What is Calcium Stearate?

Definition

Calcium Stearate is a calcium salt of Stearic Acid containing Calcium. It is part of the metallic stearates family. white Calcium Stearate powder that has hydrophobic characteristics.

Industrial Applications

Calcium Stearate is a functional additive (Unlike fillers). Applications include:

- Lubricant and processing aid in plastics.

- Formulations containing PVC Stabilisers.

- Mould-release agent.

- Anti-caking agent in powders.

Calcium Stearate in PVC has an essential role in PVC applications, especially during the extrusion and molding phases.

Benefits of Calcium Stearate

- Improves melt flow and processing efficiency.

- Prevents material from sticking to machinery.

- Enhances surface smoothness.

- Provides moisture resistance.

High-quality Calcium Stearate powder ensures consistent processing and reduced downtime.

Applications in PVC Industry

Role of Calcium Carbonate in PVC

Calcium Carbonate provides the strength and bulk for rigid and flexible PVC, and its main applications are within the optimized PVC pipe additives systems used throughout the production of pipes, profiles, and sheets. A proper choice in particle size provides the ability to extrude smoothly with mechanical stability.

Role of Calcium Stearate in PVC

Calcium stearate in PVC is primarily an internal lubricant and acid scavenger. It improves melt flow while reducing die build-up and providing protection against thermal degradation of the polymer during the manufacturing process.

Together, these materials complement each other rather than complete another important conclusion when comparing Calcium Carbonate vs Calcium Stearate.

Applications in Plastics, Paints, and Other Industries

Plastics Applications

- Calcium Carbonate improves the rigidity of plastics and helps maintain their size and shape.

- Calcium Stearate makes it easier for plastic to be removed from its mold and allows for faster production.

Many plastic compounders combine Calcium Carbonate powder and Calcium Stearate powder as a balanced formulation when making plastic products.

Paints & Coatings Applications

- Calcium Carbonate helps to extend the use of paint by increasing its opacity and Matt finish.

- Calcium Stearate also enhances the water resistance and smoothness of paint surfaces.

Using both materials together, manufacturers can meet their desired performance level without incurring excessive costs.

Choosing the Right Material for Your Industrial Application

Factors to Consider

- End-product Design (Strength or as Processing Aid).

- Type of Processing Method Used (Extrusion, Injection Molding, Coating).

- Cost Control requirements.

- Expected Surface Finish and Durability.

When to Choose Calcium Carbonate vs Calcium Stearate

- When there is need of bulk, rigidity or cost control, use Calcium Carbonate

- When there is a need for lubrication, flowability or heat stability, use Calcium Stearate.

Understanding Calcium Carbonate vs Calcium Stearate from a functional perspective, you’ll help reduce the chance of formulating errors, and improve your consistency.

Why Choose Sukhmani Impex for Calcium Carbonate and Calcium Stearate?

Supplier Reliability and Certifications

Sukhmani Impex is a reliable manufacturer in India and an internationally recognized exporter who delivers a reliable supply of material to the USA, Brazil, the UAE, Germany, and Spain, among other countries. Strict quality control ensures every batch meets industrial standards.

Product Range and Grades

- Several different grade levels of Calcium Carbonate powder for use in the manufacture of PVC, plastic, and paint.

- High-purity Calcium Stearate powder for use in stabilizing and lubricating PVC.

- Technical assistance with optimizing material formulations.

Conclusion

Calcium Carbonate vs Calcium Stearate are materials that should not be compared in order to determine the better substitute; instead, they are materials used to develop specific performance attributes of a product as well as the end-use application of the product. Calcium Carbonate acts as a reinforcing filler that increases the tensile strength and rigidity of a product at an economical price; Calcium Stearate serves as an essential processing aid that enhances the lubrication, flow properties, and thermal stability of a product.

When used together, especially in Calcium Stearate in PVC formulations and advanced PVC pipe additive systems, they enhance product consistency and facilitate smoother processing, while improving long-term durability, allowing the manufacturer to achieve optimum technical performance while maintaining optimum cost performance.

For manufacturers who are looking for a reliable source for quality grades and expert technical assistance, Sukhmani Impex is the perfect partner. Providing high-quality products of Calcium Carbonate and Calcium stearate gives manufacturers the ability to formulate with confidence and ensure that they meet the performance standards of their industries with their PVC, plastic, and other related applications.

Contact Us

- Product specifications

- Latest Calcium Carbonate & Calcium Stearate prices

- Samples for testing

- Bulk and export supply details

FAQs

1. What is the main difference between Calcium Carbonate and Calcium Stearate?

Calcium Carbonate is an inorganic filler used for strength and cost reduction, while Calcium Stearate is an organic processing aid that improves lubrication, flow, and heat stability.

2. Can Calcium Carbonate and Calcium Stearate be used together?

Yes, combining both allows manufacturers to achieve improved rigidity, smooth processing, and cost-effective formulations in PVC, plastics, and paints.

3. Which industries commonly use these materials?

PVC manufacturing, plastic compounding, paint & coatings, rubber, and construction materials frequently use Calcium Carbonate and Calcium Stearate.

4. Why choose Sukhmani Impex for these materials?

Sukhmani Impex offers high-purity grades, consistent quality, international certifications, and technical support for optimizing formulations.

5. Can Calcium Carbonate reduce production costs?

Yes, as a cost-effective filler, it lowers raw material expenses while maintaining product strength.