Fluid-X vs Polyethylene Wax: Which One is Right for Your Industry?

In the world of industrial waxes, choosing the right product can significantly impact efficiency, durability, and overall performance. Two popular options in the market are Fluid-X vs Polyethylene Wax. While both serve a variety of applications, understanding their differences can help businesses make an informed decision.Compare Fluid-X and polyethylene wax for industrial applications. Find the best solution with Sukhmani Impex today!

Understanding Fluid-X

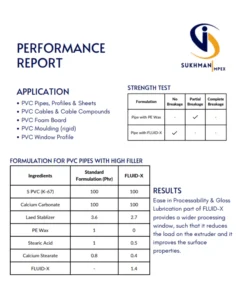

Fluid-X is a modern, high-performance wax specially made for excellent lubrication, dispersion, as well as for surface protection. It is often used in sectors like inks, coatings, plastics. Because of its exceptional stability to thermal conditions and chemicals. In contrast to traditional waxes, Fluid-X offers better dispersion and is notable for its properties to elevate the gloss and the scratch resistance in coatings.

PRODUCT DESCRIPTION FLUID-X is a single-pack industrial lubricant used for Filler-Loaded Polymer Compounds such as PVC and TPE. Its thermal stability and high brightness character makes it favourable for use as both internal and external lubricant used in PVC Processing. FLUID-X is very effective in dispersion of higher contents of calcium carbonate with an increase in the overall gloss and strength. Provides considerable anti-sticking properties to the PVC melts achieving a smooth and glossy surface on the end product. It coats the primary particles of PVC & assists the breakdown of particle structures, resulting in proper gelation of PVC Compounds.

KEY BENEFITS: Better Gloss & Surface Finish, Improved Strength, Reduces Machine Friction, Efficient Processing for faster production, and maintains Product Colour Stability.

Traditional Polyethylene Wax: A Time-Tested Solution

Polyethylene (PE) wax has been the go-to material in industries for many years as it is readily affordable and can be used in various ways. Being derived from a polyethylene polymer, it is most commonly used in the plastic, rubber, textile, and coating industry (commonly used in plastic/rubber/textile/coating). Apart from PE wax providing lubricity, slip properties, and being thermally stable, making it a good choice for different conditions in the production process. PE wax is the best option for good lubricity, slip properties, and thermal stability, resulting in the machine running more effectively. Nevertheless, cit makesompared to Fluid-X, its performance advantages should remain a subject of concern for potential use in luxury applications.

Key Differences Between Fluid-X and Polyethylene Wax

|

Feature |

Fluid-X | Traditional Polyethylene Wax |

|

Thermal Stability |

High |

Moderate |

|

Lubricity |

Enhanced |

Standard |

|

Dispersion Properties |

Superior |

Moderate |

|

Scratch Resistance |

Excellent |

Good |

|

Surface Gloss |

High |

Moderate |

|

Chemical Resistance |

High |

Moderate |

| Cost | Affordable |

Budget-friendly |

Choosing the Right Wax for Your Needs

When it comes to choosing between Fluid-X and the regular PE wax, it is vital that you take into account your specific industrial specifications. In order to get a wax that provides you with higher thermal resistance, better dispersion, and a smoother surface finish, Fluid-X is the one to go for.

Conclusion

Both Fluid-X and polyethylene wax have their advantages, and the right choice depends on your application needs. For industries requiring advanced performance and enhanced properties, Fluid-X is the future. Meanwhile, traditional PE wax remains a cost-effective and reliable solution for standard applications.

Sukhmani Impex is a respected supplier of industrial waxes of superior quality, which include the Fluid-X wax solutions that are used in different kinds of industries. We are firmly engaged in ensuring high standards of quality and the satisfaction of our customers mainly by offering top-quality raw materials to be used in many fields.

For premium-quality wax products, contact Sukhmani Impex today and explore our range of industrial wax solutions